CASE STUDIES

|

|

Challenging Horizontal Well with Expected Casing Wear

|

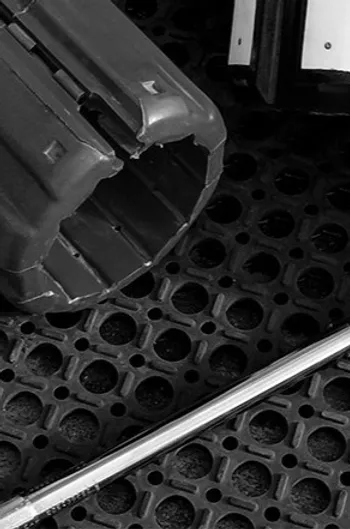

Casing Protection

& Heat Checking Prevention Due to Non-Rotating Protectors |

18% Torque Reduction After Installing WWT

Non-Rotating Protectors |

||

|

A series of similar horizontal wells in the Middle East were drilled and showed significant wear on the 7" liner from kick off point (KOP) to liner shoe after drilling 6-1/8" sections with NRPs installed

|

An operator failed a 16" casing pressure test on a previous well due to excessive wear and probable heat checking. WWT's Non-Rotating Protectors (NRPs) were deployed for the next similar well as a solution to prevent further incidences by protecting the casing on multiple hole sections

|

An operator experienced high torque while drilling the 8-1/2" section of a 4km build-and-hold directional well. WWT performed torque and drag analysis to identify the major side force areas and decide the optimum placement for WWT Non-Rotating Protectors (NRPS)

|

||

|

Learn More |

Learn More |

Learn More |

||

|

Increased Casing Protection Measurably Reduces Metal Collected

|

No Casing Wear Detected After More than 9 Months of Drilling in a HP/HT Well

|

|||

|

An operator required casing protection while drilling offshore development wells in 1, 100m of water. The 1/2-¼" X 14-¾" and 9-½" sections were drilled with 5-⅞" range three (R3) drill pipe. Limited casing logging services were available to the operator. This required a pragmatic approach to casing protection by monitoring metal returns at the ditch magnets

|

The exploratory (HP/HT), onshore well was originally planned to be drilled to 6,500m total depth (TD), making it one of the deepest wells in the country. In addition, the historically low ROP of 1 m/hr and long exposure of production casing to drill pipe rotation caused a concern for casing wear. WWT Non-Rotating Protectors (NRPs) were deployed as a solution

|

|||

|

Learn More |

|

|||